Localized Isotope Specific Characterization on Fuel Pellets

The Nuclear Materials Group at UC Berkeley’s Nuclear Engineering Department has discovered a novel application to utilize a technique to precisely quantify isotopes in hazardous materials under extreme conditions. This breakthrough, led by PhD student Chai Peddeti and Professor Peter Hosemann, with contributions from undergraduate and master’s students, introduces a novel femtosecond laser ablation manufacturing and analysis system. The laser tool allows for the fabrication of mesoscale sample geometries while simultaneously characterizing the isotopic composition of materials. Earlier projects have demonstrated the system’s potential to significantly advance nuclear materials research by enabling precise manufacturing and analysis on a microscopic scale, unlocking new possibilities in the field.

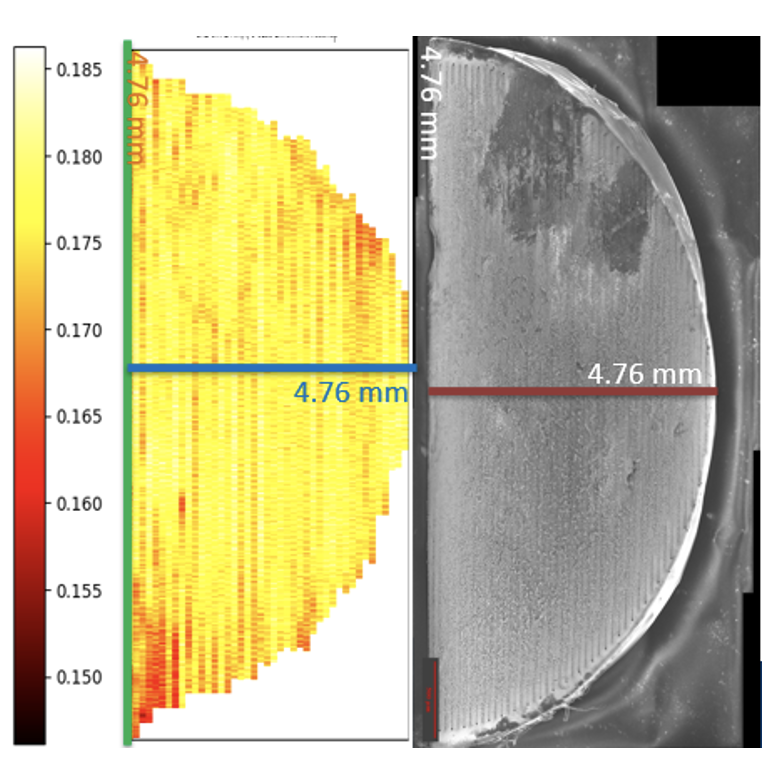

An undergraduate capstone project (Students: Christopher Escobar, Marc Anthony O’Shea, Erica Badaracco, Eric Yu) successfully demonstrated this tool on fresh HALEU (High Assay Low Enriched Uranium) fuel (see figure below). Additional contributors are the undergraduate students Izaak Meyerovich and Litzy Cerezo. This development was in collaboration between Los Alamos National Laboratory and UCB-NE-ME-MSE departments. The method enables precise isotope ratio mapping (e.g. U235/U238) with a micrometer-level precision on HALEU fuel pellets. The students gained valuable hands-on experience with HALEU fuel and the demonstrated that the tool is radiation hardened. This analysis system will be available to Department of Energy (DoE) researchers through the Nuclear Science User Facility (NSUF).

UGS Christopher Escobar, Marc Anthony O’Shea, Erica Badaracco (Eric Yu not in photo).

UGS Christopher Escobar, Marc Anthony O’Shea, Erica Badaracco (Eric Yu not in photo).

Iostope specific heat map (U235/238 ratio on a fuel pellet).

Iostope specific heat map (U235/238 ratio on a fuel pellet).

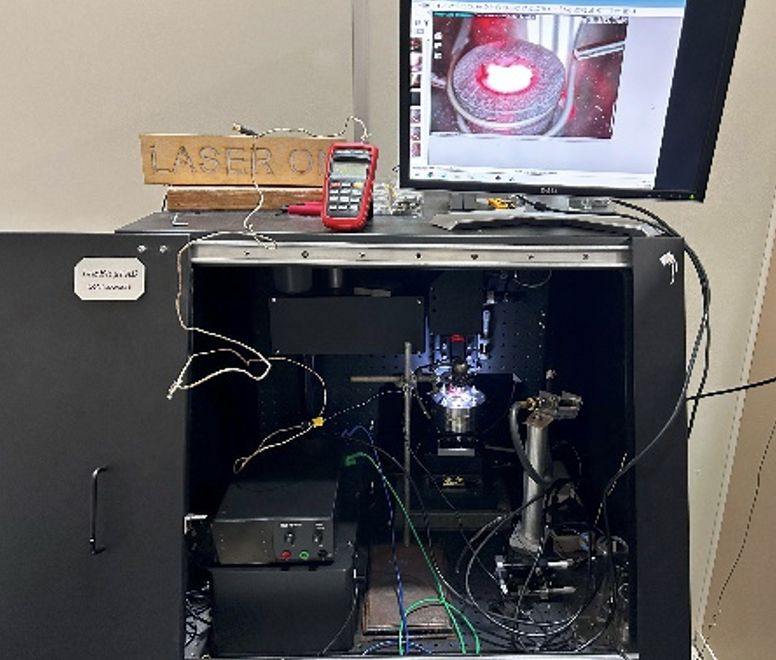

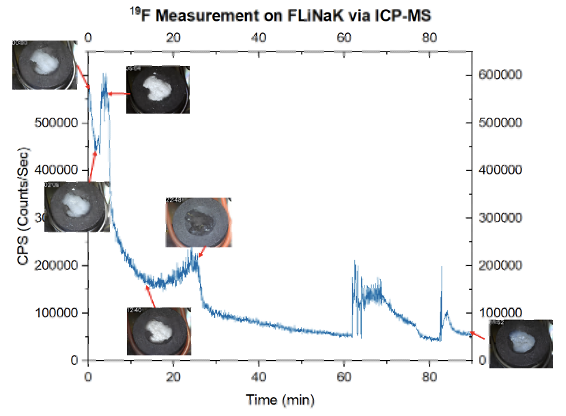

The tool was further enhanced to address more extreme environments, particularly in tackling corrosion-an ongoing challenge in advanced nuclear systems, such as heavy liquid metal and molten salt environments. Understanding corrosion processes and quantifying fission product content in these media requires not only elemental analysis but also precise isotope characterization. The team demonstrated that Laser Ablation-Inductively Coupled-Mass Spectroscopy (LA-ICP-MS) and Laser Induced Breakdown Spectroscopy (LIBS) can be employed at high temperatures on liquid salts and metals. Chai Peddeti played a key role in this advancement by constructing a radiological controlled cell that enables heating in a controlled environment while performing LA-ICP-MS and LIBS on samples in liquid phase. With this setup, Chai was able to observe the change in chemistry (such as lorine and Chromium, content) as temperature and environmental factors (like moisture) varied. Moreover, he was able to quantify the isotopes present-crucial when working with fuel salts. This method currently stands as the only available technique for in-situ isotope quantification during the corrosion or fission process.

This innovation was made possible with the support of the Integrated Research program (IRP) Nuclear Energy University program titled “Bridging the gap between experiments and modeling to improve design of molten salt reactors” led by Professor Massimiliano Fratoni.

Recently the work was also expanded to cover fusion environments. Together with visiting scholar Nicole Virgili, the team showed that the technique is also suitable for studying Pb-Li eutectic -a potential fusion breeding blanket – and molten tin (Sn). Again, direct in-situ monitoring of elements and isotopes enables a real-time, in-operando quantification of corrosion and transmutation product content.

The high sensitivity of LA-ICP-MS allows for the quantification of isotopes down to the parts per billion (ppb) level, enhancing system safety and bolstering confidence in the associated models used for nuclear systems. Coupling this method with electrochemical measurements will allow for simultaneous quantification of elements, speciation and isotopes during operation in the liquid.

In the context of next-generation nuclear reactors and future fusion power plants, where the use of molten salts or heavy liquid metals pose increasing challenges due to corrosion phenomena, the introduction of LA-ICP-MS as a real-time corrosion monitoring tool offers a new approach towards a more sustainable and safer nuclear future, contributing to the global cleaner energy technologies goals.

Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS)

Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS)

Nicole Virgili

Nicole Virgili

Professor Peter Hosemann (Photo by Adam Lau/Berkeley Engineering).

Professor Peter Hosemann (Photo by Adam Lau/Berkeley Engineering).

PhD student Chai Peddeti working on the Mass spec (Photo Credit: AJ Gubser).

PhD student Chai Peddeti working on the Mass spec (Photo Credit: AJ Gubser).

![BE_System_RGB (5) [Recovered]_Lead Line BE_System_RGB (5) [Recovered]_Lead Line](https://nuc.berkeley.edu/wp-content/uploads/2024/07/BE_System_RGB-5-Recovered_Lead-Line-e1726454265177.png)